The quality of our windows lies in the details

The quality of our windows lies in the details

In order for upvc windows and doors to be truly high quality and reliably serve their owners for many years, it is important that the production of plastic structures is carried out in strict accordance with all standards and quality control. We will tell you how a responsible approach to every detail affects the overall quality of the windows.

Input control of all components to ensure compliance with REHAU requirements, while maintaining appropriate documentation. Measurements of the thickness of each reinforcement batch, adhesion of remote frames, proper mixing of gaskets, and performance of each molecular sieve batch.

Creating technical conditions for recycling profiles and components (room temperature on cold days and lighting). Compliance with the necessary conditions ensures proper work quality.

Mixing the sealant. The sealant curing occurs as a result of mixing two components (base and hardener) and the subsequent polymerization reaction.

Proper mixing of the sealant. The correct consistency and proportions during the mixing of the sealant allow for obtaining a high-quality sealant with good adhesion.

Adhesion of the base layer. The sealant is applied to the side surface of the remote frame and serves as an additional means of securing the frame to the glass in the production of double-glazed windows, and in the finished product, it is the main barrier to the penetration of water vapor from the atmosphere into the space between the glass, providing 93-95% tightness of the product as a whole.

Adhesion of the secondary sealant. Excellent adhesive properties ensure complete sealing of the double-glazed window, which directly affects the energy-saving properties of the window.

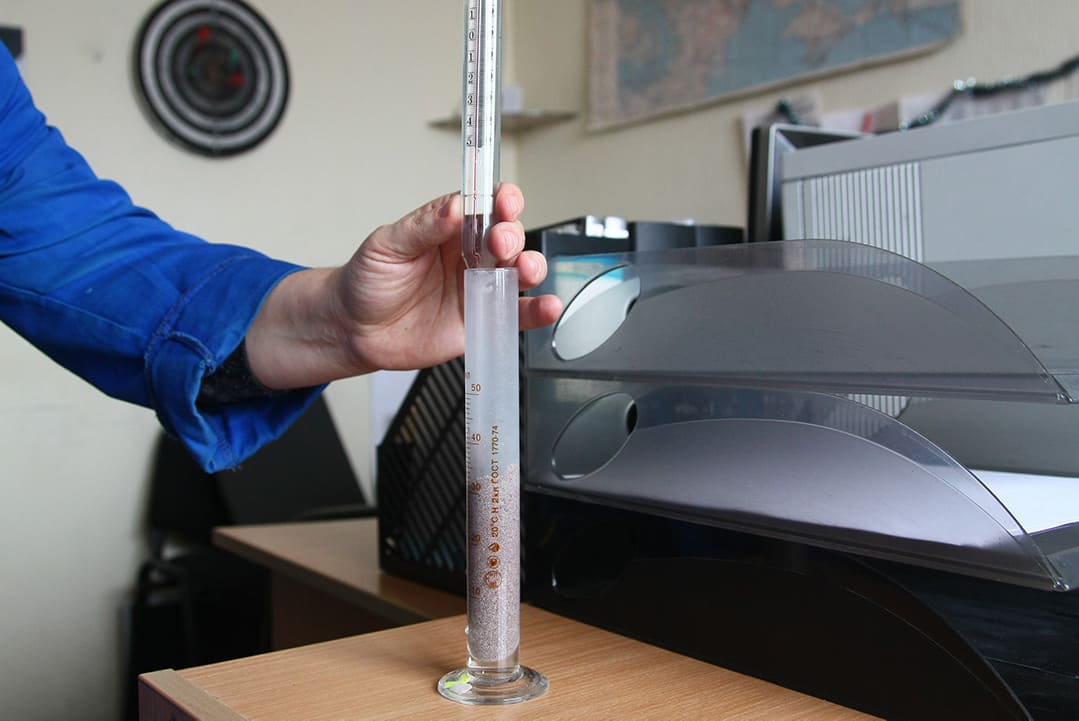

Delta molecular sieve test, check before each change. This is a rapid method of assessing adsorbent effectiveness, based on the heat release effect by the molecular sieve upon immersion in water. The more water absorbed by the adsorbent, the more heat is generated.

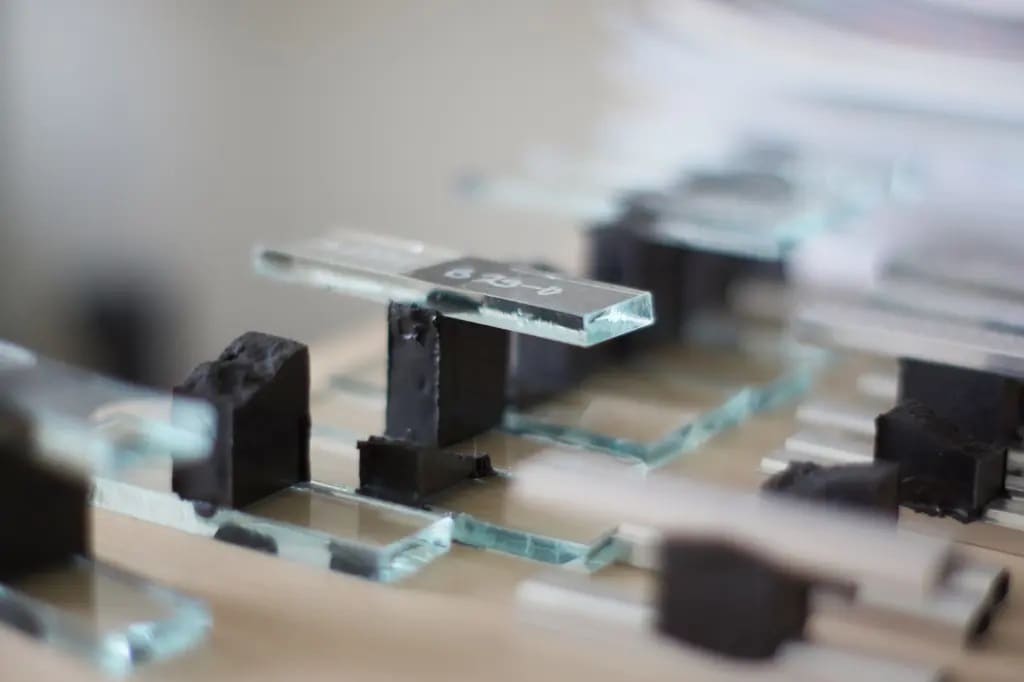

Adhesion of the spacer frame. Remote frames have good adhesion to sealants, as a result of which double-glazed windows achieve excellent tightness.

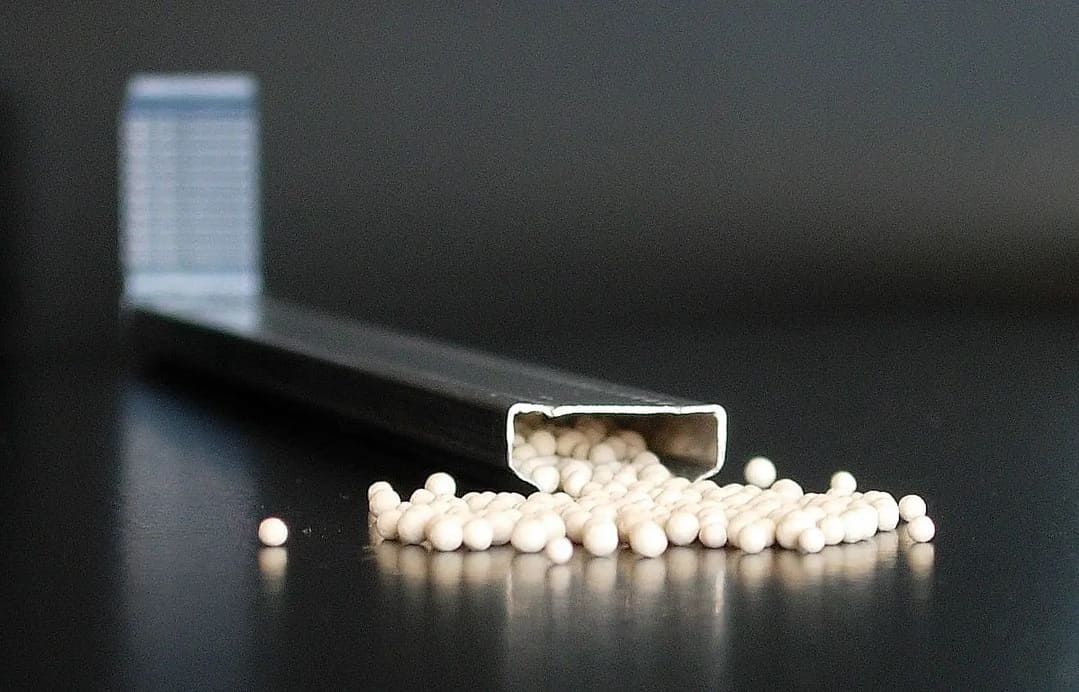

Using high-quality molecular sieve. The NEDEX sieve is specifically designed for the production of double-glazed windows, its quality is confirmed by certificates from world-renowned organizations, and it also has high performance, including moisture absorption.

Professional primary sealant and Fenzi polysulfide. It provides reliable sealing of the double-glazed window and minimizes gas leakage (no more than 2% per year).

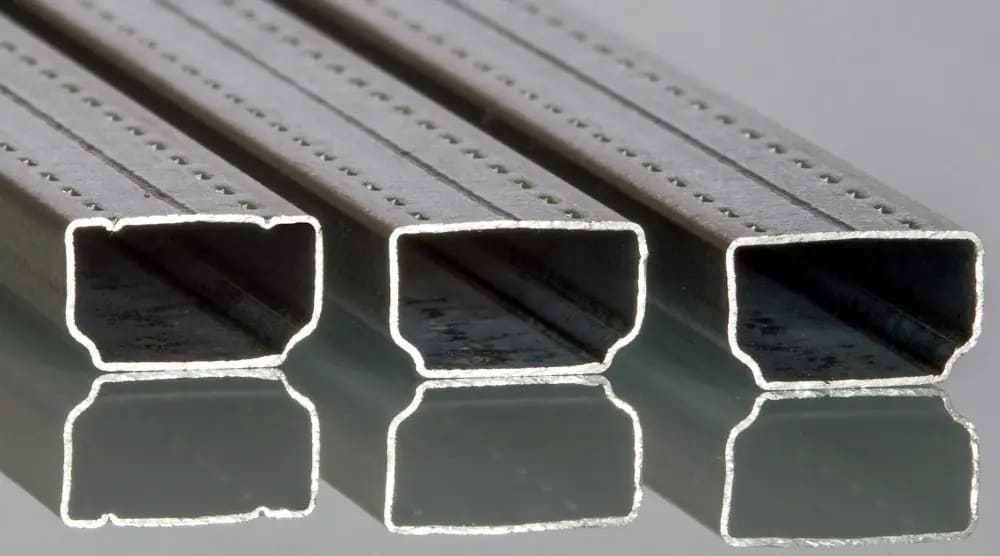

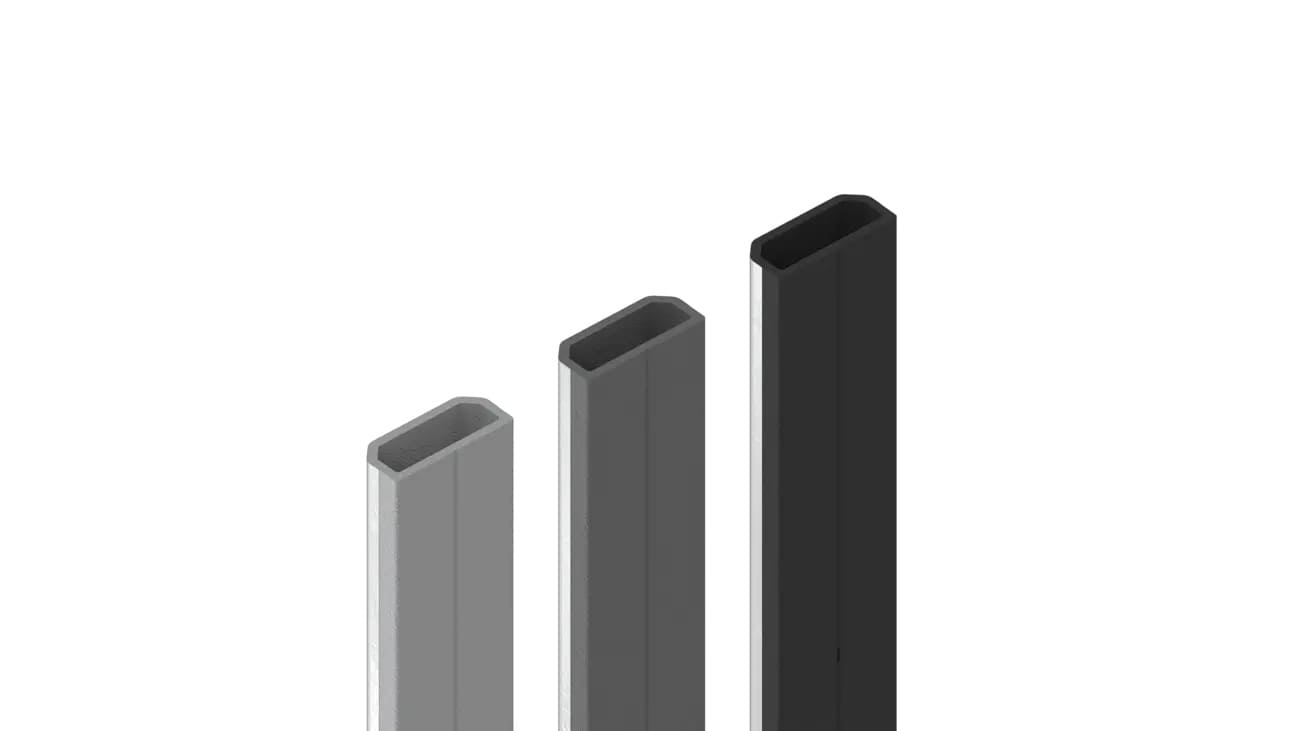

Remote frame only from European manufacturers:

- Aluminum Profilglass. Remote frame from an Italian manufacturer, popular and reliable guarantee has been time-tested;

- Plastic spacer Swisspacer. Remote frame from a Swiss manufacturer, which minimizes the possibility of condensation on the perimeter of the double-glazed window.

Primary and secondary sealant filling chambers have a width of 10 to 11 millimeters.

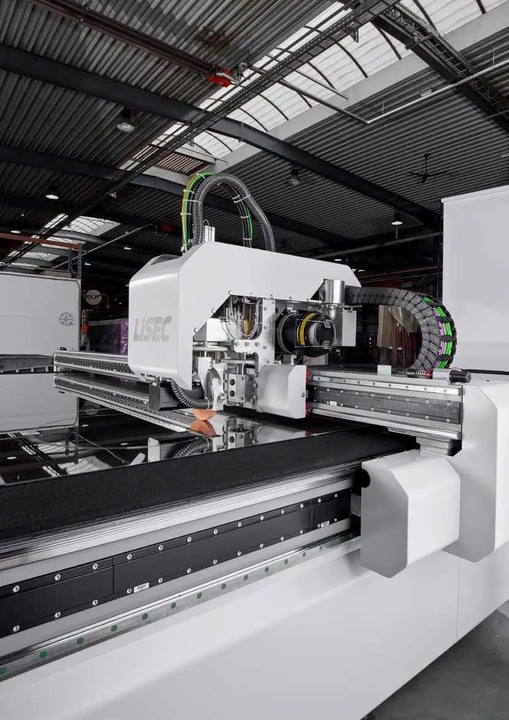

The best Austrian equipment "Lisec" for the production of double-glazed windows. The line fully covers the needs for producing energy-efficient double-glazed windows.

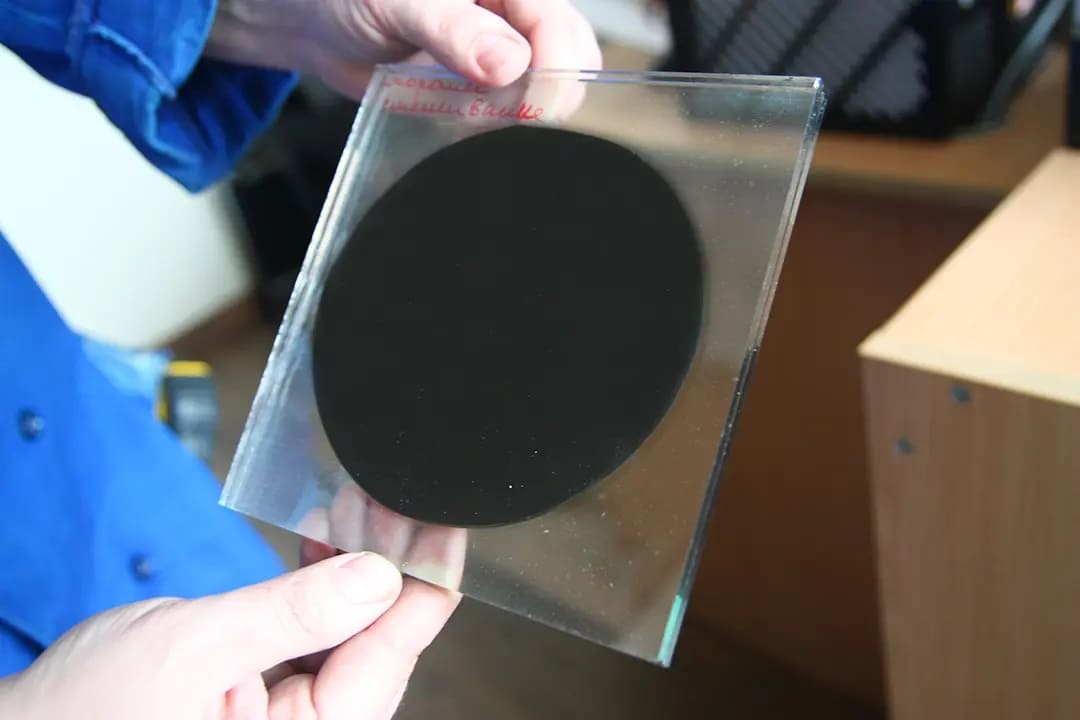

Only M-0 and M-1 brand glass. Such glass is distinguished by its high quality, transparency and absence of defects.

All components for the windows are exclusively of European manufacture and are purchased only from trusted suppliers.

European equipment for the production of windows and double-glazed windows. Automated lines allow windows to be made in the shortest possible time with consistently high quality.

WTC employees. The technical control department monitors compliance with all norms and standards in production.

Regular inspection of the geometric dimensions of windows, diagonals, welding seam distance between. Every product at the factory undergoes stringent quality checks.

Measurements of the thickness of each batch of reinforcement. The reinforcement profile is the skeleton of the window. It is important that the window stands and retains its shape. Dostawaokien uses a reinforcement thickness of 1.5 mm and regularly checks this parameter.

Test the profile for hacking. Regular checks of the profile's resistance to hacking are carried out by the company's specialists on special machines. The burglary resistance of the profile is 320 kPa and REHAU profiles can withstand a load of 570 kPa.

High-quality REHAU components. High-quality components from the REHAU Group are used in the production of the windows. The company has become a leader in the production of polymer products worldwide.

Painting. For profile painting, the window manufacturer uses only the best paint from the Swiss manufacturer FEYCO. The profile is painted on high-quality equipment using Swiss air-spray technology in special paint chambers which produce high-quality products.

Compliance with European standards. All Dostawaokien.pl products are tested and comply with all modern European standards and norms, as certified.

Behind every window manufactured is a great deal of work by people who want to create a high-quality product. Only attention to every detail allows the manufacturer to produce truly high-quality metal and plastic structures. Strict adherence to standards at every stage of production guarantees consistently high quality.